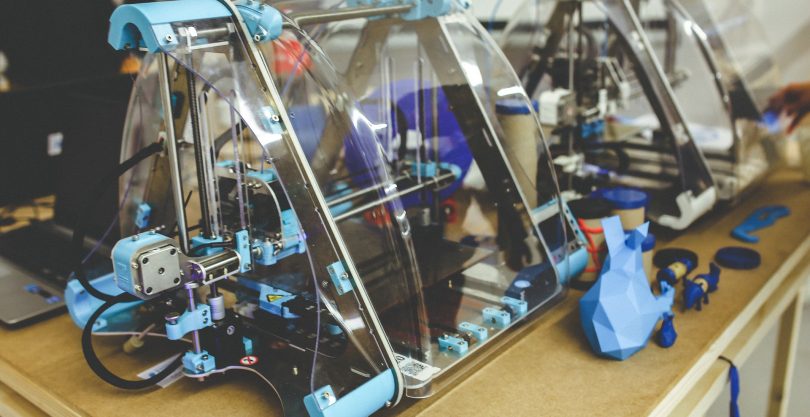

This 3D printer’s detailed guide will explain what additive manufacturing is, what materials are available, and how much 3D printers cost. We’ll also discuss how to make a 3D printer of your own! And, of course, we’ll cover the cost! Here’s our step-by-step guide! So, let’s get started! And, stay tuned for more articles like this! Until then, happy printing!

3D printing is an additive manufacturing process

In the field of design and manufacturing, additive manufacturing refers to the creation of objects by adding material to a previously flat blank. Additive manufacturing differs from subtractive manufacturing in that parts are created with a three-dimensional design instead of subtracting material from the original.

The three-dimensional model is then built up layer by layer until it reaches a solid object.

The technologies involved in 3D printing are vast and varied. However, each of them shares one main characteristic: the creation of layers to create the physical model.

The material jetting technologies include laser-sintering, powder bed fusion, and direct metal laser sintering. Each method uses a laser or a heat source to fuse the material.

Metals can be printed by using this method. Other methods of 3D printing use thermoplastics, such as polycarbonate and titanium. These technologies are highly accurate but tend to be expensive. However, they can produce parts with very good surface finishes and excellent physical properties.

Materials available for 3D printing

Among the many materials that can be used for 3D printing, plastics are the most common.

FDM technology-based 3D printing is especially popular, and these materials are available in powder and filament forms. The former is used for the sintering or SLS process, while the latter is used for the FFF process.

Each of these materials has unique characteristics that make them suitable for specific applications.

Here are some of the more common types of plastics used for 3D printing.

The materials available for 3D printing include polymer powders, metal powders, ceramic powders, fused wire, and wood-plastic composite materials.

Among them, photosensitive resin is the most popular. Other materials include thermoplastics, edible materials, and fused wire. The most popular 3D printing materials are polymer powders and photosensitive resin. To find the best material for your needs, choose the material that best suits your intended purpose and budget.

Cost of 3D printers

The cost of 3D printers will vary widely depending on the material that you use. The most common types of filament include polylactic acid (PLA), ABS, PETG, and TPU. The cost of these materials varies from fifteen to thirty dollars per kilogram.

However, the price will depend on the material you choose as well as how much it weighs.

ABS, PETG, and PLA are the most expensive types of filament, while their prices average twenty to thirty dollars per kilogram.

High-end 3D printers are typically loaded with sensors, self-tuning software, and feedback loops.

As such, they require calibration, either at the manufacturer’s factory or by an engineer installing the printer in your own home.

High-end printers are typically more expensive than entry-level models, but their reliability and low maintenance make them worth the higher price tag. However, they have several limitations. You will have to buy more expensive materials and perform more complex processes with these printers, which will result in a more complicated process.

Ways to create a 3D printer

Building a 3D printer is a rewarding experience for a variety of reasons. This type of printer can be used to make other parts, but building one on your own can be a fun academic exercise as well.

Besides being fun, building a 3D printer can teach you how to work with linear motion, electronics, and programming. And, it’s a great way to save money, too.

Before starting your 3D printing project, you’ll need a 3D model. This can be a model created from scratch or downloaded from a 3D library. Once you have the 3D model, it’s time to prepare the file for the printer.

This process is known as slicing and requires some computer software. Slicing a 3D model requires using software to cut it up into layers. The sliced file is then loaded into the printer. It can be inserted through a USB connection, SD card, or Wi-Fi. It will begin 3D printing, layer by layer.

Comments